Q-Truck completes 36 extreme and fatigue tests

Q-Truck, an autonomous heavy-duty truck developed by Westwell, has successfully passed the CAE assessment for vehicle chassis frame strength and durability. This assessment was supported by Ricardo, an internationally recognised engineering organisation. The assessment concluded that the Q-Truck chassis frame structure fully complies with the safety targets for various working conditions in complex port scenarios. The Q-Truck Chassis frame excels in safety, reliability, and durability, making it a preferred choice for customers seeking intelligent transformation in large logistics.

Authoritatively recognised for superior performance

In the search for more trustworthy intelligent partners for the sustainable transformation of large logistics, Westwell, a global leader in the driverless field, and Ricardo have conducted an all-round on-site inspection and CAE assessment of the Q-Trucks’s chassis safety, strength and durability.

The assessment was organised by Ricardo’s UK head office, which tailored a rigorous CAE assessment programme specifically for the Q-Truck using its advanced testing technology and equipment. Following a professional evaluation by Ricardo’s global experts involving real-life scenarios and 36 types of simulation verification, the assessment confirmed that the Q-Truck chassis meets safety requirements under various working conditions in complex port scenarios.

Additionally, the outstanding durability of the chassis potentially exceeds port customers’ needs for over 10 years.

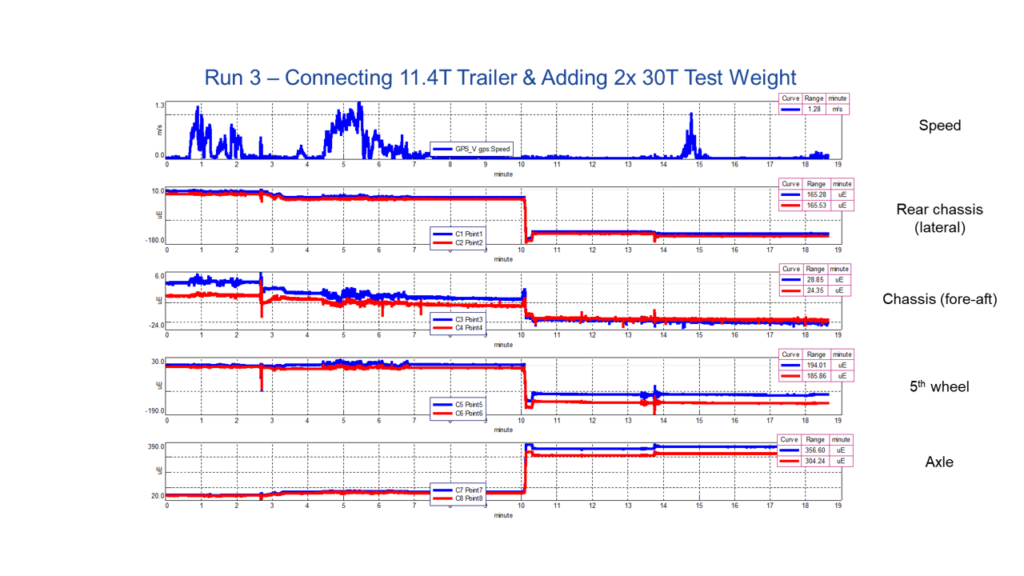

Based on vehicle fatigue loads and extreme loads collected by Ricardo, the tests mainly cover chassis strength and durability. Under Ricardo’s supervision, the core results highlighted:

Firstly, the scenarios demonstrated that the Q-Truck chassis meets the required strength standards.

The actual test was conducted by collecting road spectra and stress-strain data during operations such as connecting and disconnecting from the trailer, accelerating and decelerating, turning, and emergency braking at the port.

Secondly, simulation verification confirmed that the Q-Truck’s chassis strength and fatigue resistance meet usage requirements.

Q-Truck successfully passed virtual simulation tests for 36 different working conditions. The analysis, performed remotely by Westwell Engineering under Ricardo UK Ltd.’s supervision, involved nearly unlimited fatigue cycle simulations to accommodate extreme conditions such as large speed bumps and road debris. The tests and simulations, set up with maximum accelerations of 2g in the X direction, 3g in the Y direction, and 3g in the Z direction, far exceeded the industry standards of 0.6g in the X direction, 0.4g in the Y direction, and 2.5g in the Z direction.

Q-Truck also successfully passed the chassis strain test during actual terminal operations, including the heavy container drop test. Furthermore, it complied with safety operation targets in 36 rigorous limit and fatigue condition tests, greatly exceeding the requirements for 10 years of use in the harbour. Based on Westwell’s analysis, all safety coefficients exceeded 1.45, compared to the general standard of 1.0-1.2.

Ricardo is a multinational consulting firm focused on strategic, environmental and engineering solutions. With more than 100 years of engineering excellence and a team of more than 3,000 technical experts, it has been committed to providing leading sustainable solutions in the transport and energy safety industries.

READ: Westwell shines at TOC Europe, leading global logistics towards green and sustainable growth

Reliable chassis coverage for multi-scenario applications

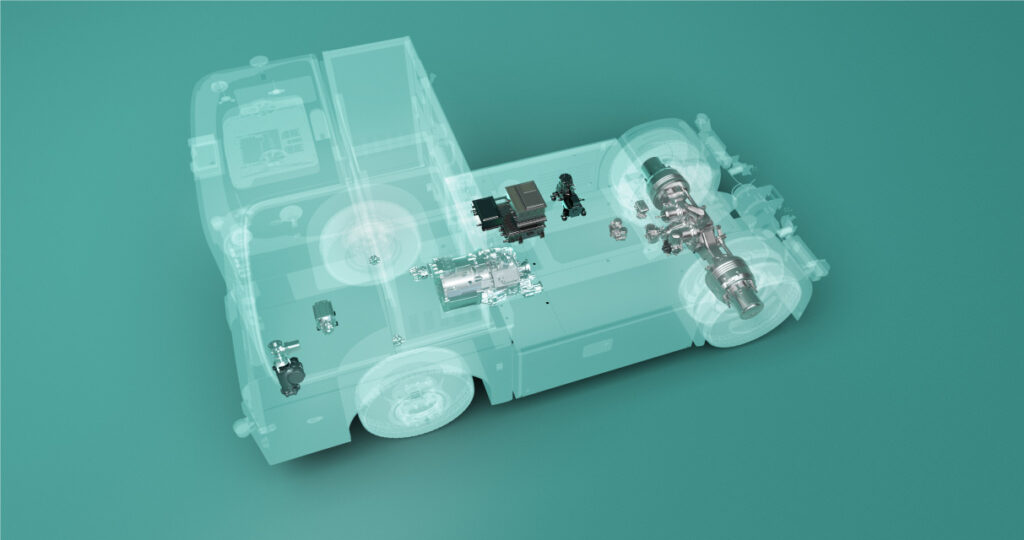

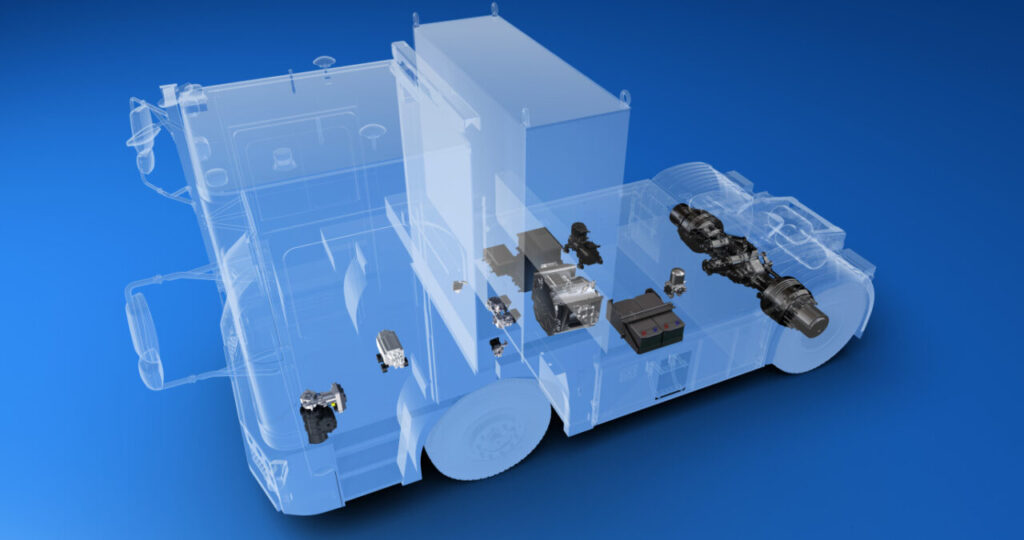

The same chassis certified and evaluated in this assessment is also used in the E-Truck, Westwell’s upgradeable autonomous smart electric heavy-duty truck. Westwell has created the Qomolo intelligent driving brand, with a product line covering various vehicle types such as unmanned driving and autonomous driving. Among them, the unmanned heavy truck Q-Truck and the manned E-Truck continue the “modular” design of the Qomolo family, sharing a chassis architecture platform that meets the green, intelligent transformation needs of customers in various scenarios such as ports, land ports, and industrial parks.

Facing complex operating environments such as container stacking and transportation, Westwell has also strengthened the customised design of the vehicle chassis. This allows it to cope with extreme climate challenges and various unavoidable working conditions, providing hard-core technical support for the efficient, safe, and sustainable operation of intelligent commercial vehicles.

The E-Truck is an intelligent, pure electric commercial vehicle tailor-made by Westwell for customers undergoing new energy and low-carbon transformation in large logistics operations. It is mainly used for field transportation in various enclosed environments, speeding up the flow of goods and helping efficient and accurate operations. As the world’s first intelligent networked new energy-heavy truck capable of upgrading to unmanned driving, the E-Truck supports autonomous driving upgrades throughout its life cycle and can flexibly switch “manned and unmanned driving” modes after upgrading.

The shared chassis architecture platform also lowers the barrier for upgrading to autonomous driving in the E-Truck, providing customers with a more flexible and cost-effective solution. When customers need autonomous driving upgrades, they need not replace the vehicle or purchase additional equipment but simply add sensor modules, autonomous driving computing units, and OTA remote online updates to the existing E-Truck vehicles to complete the upgrade quickly.

READ: Westwell and Roland Berger release the ‘Freight Logistics Decarbonization Whitepaper’

Full-cycle services to reinforce security

Since the establishment of the Qomolo intelligent driving brand, efficiency, safety and sustainability have been rooted in the brand’s DNA. With a commitment to innovation in AI, new energy, and stringent safety guidelines, Westwell has been building benchmark cases of autonomous driving applications in China, Thailand, Abu Dhabi, the UK, Egypt, Singapore Malaysia, Mexico and other parts of the world, with a proven track record of more than four years of regular operation.

Westwell’s autonomous heavy-duty trucks are the trusted first choice for customers in the large logistics industry.

As the world’s leading technology company in the autonomous driving field, Westwell continues to innovate independently, consistently upgrading its chassis technology to remain among the world’s leading companies. In addition to this assessment, the Q-Truck and E-Truck have also passed the real test in the market and gained credibility with global customers.

To promote the intelligent transformation of the logistics industry, Westwell actively explores new quality productivity driven by “New AI and Green Energy”, which runs through every link of logistics transportation, production, and operation. In the context of long-term sustainability, both Westwell and Ricardo are at the forefront of innovative technology, working together to create a more efficient, safer, and cleaner logistics blueprint through sustainable technological solutions.

Westwell looks forward to more high-quality global partners joining this green initiative.

During PTI’s Container Terminal Automation Conference (CTAC), which wrapped up in Valencia on 17-18 April 2024, we had the pleasure to sit down with Ji Zhang, Regional Director at Westwell. In this exclusive interview, we delved into the company’s groundbreaking journey in autonomous fleet operation within container terminals.