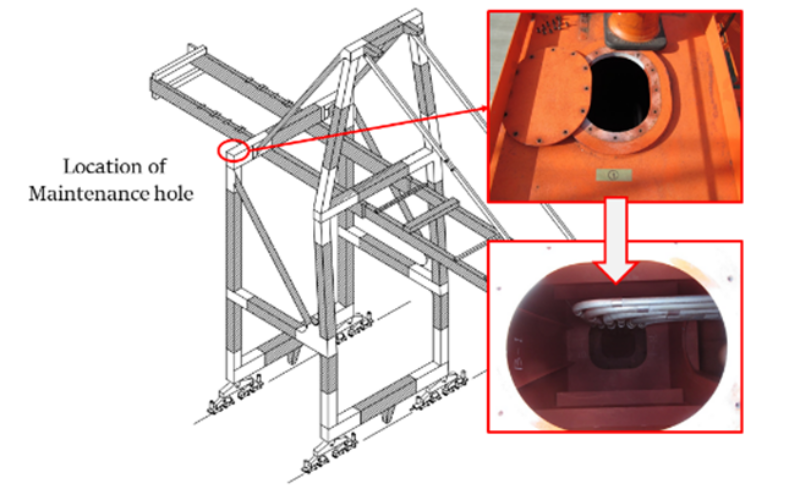

MITSUI E&S Co., Ltd. (MITSUI E&S) and Liberaware Co., Ltd. (Liberaware) have deployed the IBIS industrial drone to inspect the interior of a quayside container crane in a demonstration experiment.

Liberaware’s small drone, IBIS, was specially designed for indoor spaces.

It was used in this demonstration experiment to take a video of the internal structure of the crane and the recorded video was then evaluated in an office.

This method was used instead of continuing the conventional inspection method that requires inspection workers to enter the structure.

It was confirmed that inspection using this new technology could improve the safety of inspection workers, improve the inspection quality through video recording, and shorten the period of after-inspection-investigation needed before the repair work.

READ: Port of Klaipėda carries out drone emissions monitoring

As for the detailed periodic evaluation of container cranes and in response to customer requests, MITSUI E&S reported that it is considering providing a service for the inspections of the internal structures of the container cranes by using IBIS in the future.

MITSUI E&S is also considering linking the inspection results with the Next Generation Crane Monitoring System (CARMS) developed by MITSUI E&S to enhance the efficiency of crane maintenance and management.

Earlier this summer, the Port of Rotterdam announced that the first drone vertiport of the Netherlands has become operational, following the landing of a multirotor drone.

More recently, the Port of Rotterdam gained authorisation for the first time to test a long-distance drone for inspections and supervision operations.