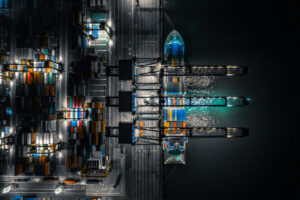

Five Continents International Container Terminal (FICT) Tianjin Port has hit several operational and productivity milestones after an extensive yard modernisation project that included retrofitting 31 cranes with Navis N4.

Originally built to handle 1.5 million TEU, Tianjin Port exceeded its design capacity and now operates at 2.7 million TEU annually.

Due to its rapid growth, Tianjin Port prioritized investing in tools and technology to aid its business operations as it scaled.

Technical Paper: 30 Years of Port Robotics

In 2019 Tianjin Port launched a project to modernise its yard by automating its fleet of 31 manually operated rail-mounted stacking cranes. With the support of Navis and ZPMC, the cranes went live with N4 in record time and were able to perform critical tasks including yard planning, vessel planning, ARMG scheduling and dispatching and prime mover/tractor-trailer scheduling and dispatching, quickly.

Other operational gains Tianjin Port has seen in the past year from its N4 implementation include:

- Increased hourly production reaching 35.2 TEU per hour/A-RMG

- Increased yard throughput capacity by 20% y

- Yard vessel berthing time decreased by 8.3 %

- RMG operators reduced by 30.3%

- OTR truck stagnation reduced time by 45.6%

- Energy consumption of a single box went down by 60%, compared to the end-loading process

“Partnering with Navis and ZPMC for our modernisation project has helped us achieve our business objectives of increased automation, to allow us to handle the high amount of cargo our port sees every day,” said Lin Hongwei, Deputy General Manager of Tianjin Port.

“We have already experienced great results from the N4 implementation and look forward to seeing continued success.”

“As one of the busiest ports in the world, we know peak productivity is essential for Tianjin Port. Due to the rapid growth the port has experienced, automating some of its processes were key in helping them handle the extra load efficiently,” said Charlie Gerard, VP and General Manager, Asia-Pacific at Navis.