HPC Hamburg Ports Consulting experts have recently highlighted how simulation can be used to effectively achieve a clear picture of terminal quay operations during times of volatile transport volumes.

COVID-19 has dished out many shocks to the supply chain and it is more important than ever that terminal operators have a clear picture of their operations in times of volatile transport volumes as shipping companies continue to adapt their services lines and implement blank sailings.

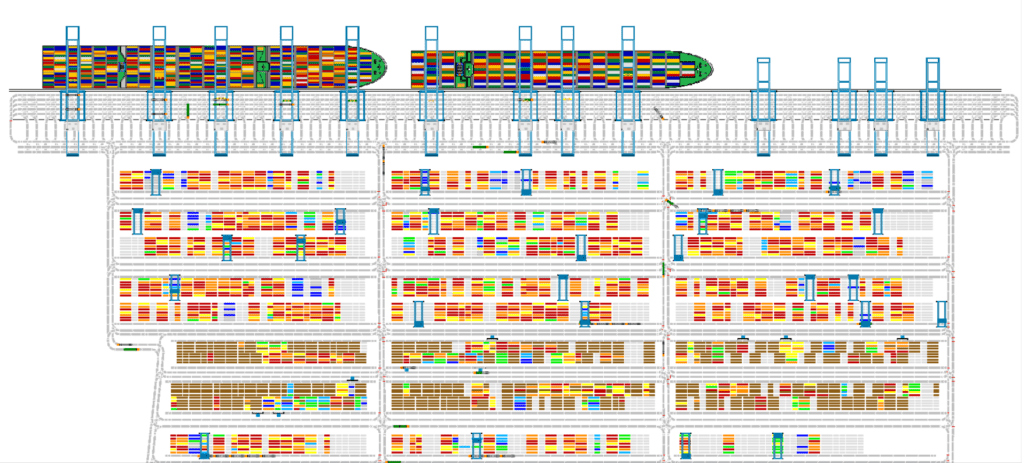

Maxim Neiser, Terminal Planning and Simulation Specialist at HPC, said in a recent paper that one measure that offers cost saving potential for terminals is temporarily taking quay cranes out of operation i.e. mothballing.

However, as Neiser noted, this is not a simple decision to take: If and how many cranes can be mothballed while ensuring unchanged service levels to vessels, considering the dynamic interdependencies of terminal and vessel operations. One of the best tools to use in order to make this decision with full visibility of its impact on operations is to use quay simulation.

“Quay simulation is not a crystal ball, but its results come with an average accuracy of about 98% percent, a figure pretty close to the reality,” Neiser said.

In his paper Neiser explores various use cases for such quay simulation and explains while it has been typically used to investigate growing container volume forecast it is also applicable when volumes are dropping as vessels cease calling at ports during times of crisis.

In another paper, Nils Kemme is Partner and port operations consultant at HPC Hamburg Port Consulting, supports Neiser’s view of simulation and also suggests its is the “one and only tool” to provide detailed and highly accurate insights into the effects of equipment reductions on terminal performance and service levels.

Kemme notes that taking any equipment out of service offers huge cost saving potential, but also provides a significant risk to operations but this can be mitigated somewhat via simulation.

To find out more read Kemme’s paper “Determining the optimal volume trigger points to right-size terminal equipment” click here.

Ultimately simulation will facilitate optimal cost saving decisions and flexibility for terminal operators, Kemme said.