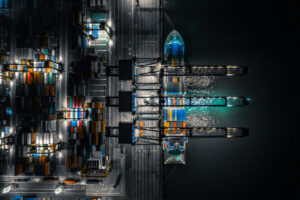

The Port of Rotterdam Authority has launched a pilot project to further optimise port and supply chain process efficiency and safety, as part of efforts to digitise operations.

In a statement, the Port Authority said the target is to make customs processes more efficient and will involve working closer with shippers, customs agents, terminals carriers and other supply chain stakeholders.

Additionally, it said increased traffic, in particular refrigerated (reefer) containers, was the key reason it launched the pilot. Inspections are carried out based on risk analyses and profiles, with country of origin and history determining whether a container should be inspected or not.

Reefers often originate from high-risk areas, which means they are also more frequently selected for inspection. As further growth is expected, it is crucial that the Port makes optimum preparations to facilitate this increased flow of reefers, it said.

Daco Sol. The Logistics, Supervision & Supply Chain Programme Manager at Fresh Produce Centre, said digtisation “enables us to reduce turnaround times and mimimise waiting times”.

“There’s a huge risk of quality losses for fresh produce. Or you may need to find other sales channels and the financial losses can run to tens of thousands of euros.

“Of course, nobody wants that. Minimising waiting and turnaround times was therefore one of our most important reasons for taking part.

“Our members import fresh produce and aim for the shortest possible turnaround time in the chain.”

Customs inspects the containers in three ways, the most common being via scanning. All large container terminals on Maasvlakte in Rotterdam have a high-tech customs scanner on site and images of the container contents are analysed by customs remotely, 24/7.

This means there is no need for containers to leave the terminal, or be opened unnecessarily and, in 95% of cases, they can be released again within 36 hours of unloading.

A second method is the physical inspection, that is carried out on the State Inspection Terminal (SIT) on Maasvlakte. The third option involves using sniffer dogs to check the relevant containers at the terminals.