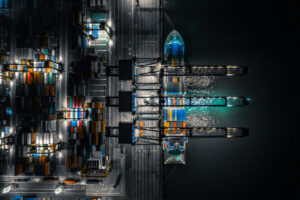

Hyster, maker of container-handling equipment, has announced that it wants to focus on its core strategy, which is to lower the cost of ownership within the industry.

The company aims to continue to improve the productivity of its products through the use of long-term testing. This involves capability-testing and the tweaking of products. The testing can take anything up to two years.

Operational efficiency is also important to the business as it is focused on reliability and dependability.

The organisation won an environmental award recently in Holland by reducing the number of shipments completed by batch.

Chris van de Werdt, sales manager for Hyster Big Trucks said: “Hyster ReachStackers and Container Handlers, used to transfer and stack shipping containers in ports and terminal operations, has already been proven to offer significant savings in fuel costs with the optimised Tier 4i / Stage IIIB engines.”

He added: “End users will further benefit with enhanced savings offered by the latestTier 4f / Stage IV-compliant models.”